Heat transfer in ceramic

27/05/2016, Pavel Procházka

Crack-free sintering of bulk ceramic material with low thermal conductivity.

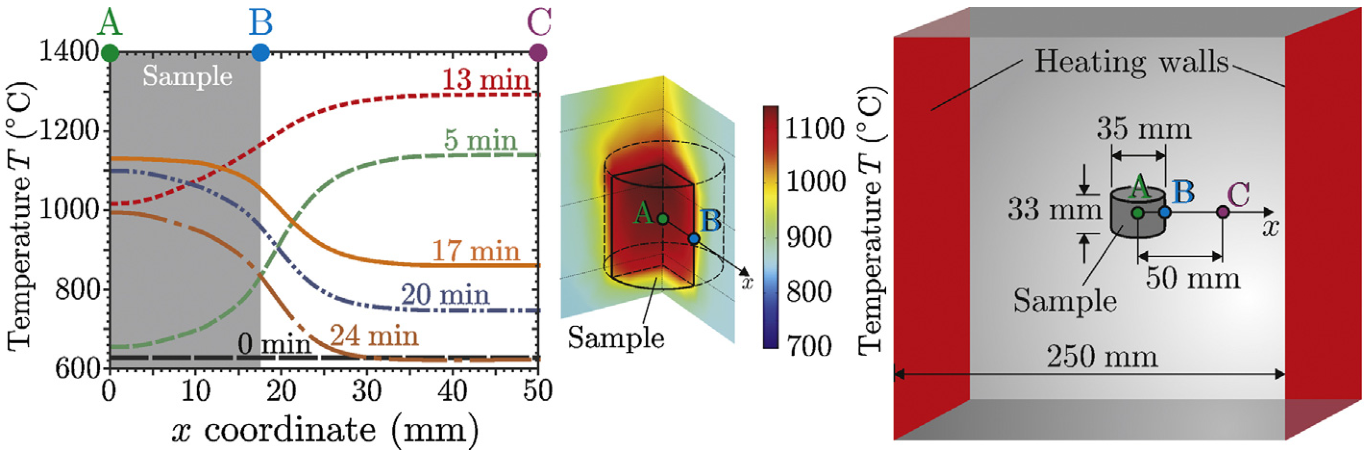

Rapid sintering is nowadays a domain of novel methods such as spark plasma sintering (SPS) or flash sintering. These methods deal with special heating and, therefore, it is difficult to describe obtained results by a conventional pressureless sintering mechanism. This work deals with specially designed pressureless rapid sintering furnace, which allows heating rates on level of hundreds degrees per minute. Sample with volume over 30 cm3 from low thermally conductive tetragonal zirconia stabilized with 3 mol% Y2O3 (3Y-TZP) was rapidly sintered to relative density of 86 % without crack formation. Experimental data were used for numerical calculations of conduction/convection heat transfer. Obtained results reveal that the maximum temperature in the sample does not exceed 1200 °C if only heating by conduction and convection is considered. Our results indicate that during rapid sintering of low thermally conductive materials radiation heat transfer is dominant in both conventional and SPS conditions.